3D Scanning Rentals Streamline Your Workflow

3D laser scanning has revolutionized industries ranging from manufacturing to architecture by allowing users to capture highly accurate digital representations of physical objects through the process of digitization. This technology offers numerous benefits, making it an indispensable tool for professionals seeking precision, efficiency, and innovation. In this blog, we will explore the key advantages of 3D scanning, its integration with 3D printing, its use in converting scans to 3D prints, and why 3D scanner rentals can be a smart choice for many projects.

Key Benefits of 3D Scanning

High Precision and Accuracy One of the most significant advantages of 3D scanning is its ability to capture extremely detailed and accurate measurements. Laser scanners can achieve precision down to fractions of a millimeter, making them ideal for industries where accuracy is paramount, such as engineering and product design. This level of detail ensures that scans are reliable for creating exact replicas or models, reducing errors in subsequent stages of production or design.

Speed and Efficiency Traditional methods of measurement or documentation can be time-consuming and labor-intensive. In contrast, 3D scanning captures thousands or even millions of data points per second, enabling rapid data collection. This speed not only accelerates project timelines but also minimizes the need for multiple site visits or rework due to incomplete data capture.

Non-Contact Data Collection Because 3D scanning is non-invasive, it can be used to scan fragile or hard-to-reach objects without risking damage. This feature is particularly useful in fields like historical preservation or when working with delicate prototypes. The non-contact nature also enhances safety by allowing scans to be conducted from a distance in hazardous environments.

Cost-Effective By reducing the time spent on manual measurements and minimizing errors that lead to costly rework, 3D scanning can significantly lower project costs. Additionally, outsourcing scanning services or opting for equipment rentals (which we'll discuss later) can further reduce upfront investments in expensive technology.

From 3D Scan to 3D Print: A Seamless Workflow

One exciting use case for 3D scanning is its integration with 3D printing technology. Here’s how the process works:

Capturing the Object: A 3D scanner captures a detailed digital model (often referred to as a point cloud) of an existing object, marking the first step in its digitization. This scan collects precise geometric data that can be processed into a format compatible with 3D printing software.

Processing the Data: Once the 3d laser scanning is complete, the raw data is converted into a mesh or CAD model using specialized software. This digital model can then be edited or optimized depending on the intended use—whether it's for prototyping, reverse engineering, or creating a replica.

Printing the Object: After processing, the digital file is sent to a 3D printer where it is fabricated layer by layer using 3d printing materials like plastic, metal, or resin. The result is a physical object that mirrors the original scanned item with remarkable accuracy.

This workflow has numerous applications: from prototyping and reverse engineering to rentals of customized objects.

Prototyping: Designers can quickly create prototypes from existing objects without needing manual redesign.

Reverse Engineering: Engineers can scan obsolete parts and recreate them using modern manufacturing techniques, which might be especially useful for companies that offer equipment rentals.

Customization: Scanning allows for custom products tailored to specific needs—whether it's medical devices like prosthetics or bespoke consumer goods.

The Benefits of Renting a 3D Scanner

While purchasing a 3D scanner might seem like an attractive option for frequent users, renting offers flexibility and cost savings for many businesses and individuals.

Access to Cutting-Edge Technology Renting allows you to access the latest models without committing to large capital expenditures. With technology evolving rapidly, renting ensures you always have access to state-of-the-art equipment tailored to your project’s needs.

Cost Savings For companies that only require occasional use of a scanner, rentals eliminate the high upfront costs associated with purchasing equipment. Additionally, you avoid ongoing expenses such as maintenance and software updates since rental companies typically cover these.

Flexibility Rentals provide flexibility in terms of choosing the right equipment for specific projects. Whether you need a handheld scanner for small objects or a terrestrial laser scanner for large-scale environments, rental services offer various options. This ensures that you always have the best tool for the job without being tied down by ownership constraints.

No Long-Term Commitment If your need for 3D scanning technology or 3D printing is temporary—such as during peak project periods or when your own equipment is under repair—renting offers a short-term solution without long-term financial commitments.

Conclusion

Whether you're looking to streamline your design process with accurate digital models or convert physical objects into 3D prints with ease, 3D laser scanning and digitization offer unparalleled benefits in terms of precision and efficiency. For those who need access to this powerful technology without investing in costly equipment outright, renting provides an affordable and flexible alternative.By embracing both 3D scanning and printing technologies—and leveraging rental options—you can unlock new possibilities in design, manufacturing, and beyond while keeping costs under control.

Engineering Product Design: Innovative Strategies

The Role of Engineering in Product Development

Engineering plays a pivotal role in the product development process, bridging the gap between conceptual design and the final manufactured product. This process is not just about creating something new; it involves the product design engineer driving innovation by optimizing designs, ensuring functionality, and delivering products that meet both market demands and technical specifications. Let's explore the key stages of engineering product development and how modern tools and technologies are transforming this field.

Key Stages of Engineering Product Development

Design Conceptualization The first step in engineering product development is turning an idea into a tangible concept, often guided by a product design engineer. Engineers collaborate with designers to create early sketches and 3D models using tools like Computer-Aided Design (CAD). CAD software allows for precise visual representations, enabling teams to experiment with different configurations and quickly iterate on designs. This stage is crucial for ensuring that the product concept aligns with both user needs and business goals, with a keen focus on ergonomics, aesthetics, and usability to enhance user comfort and efficiency.

Optimization and Prototyping Once a design concept is finalized, engineers focus on optimizing the mechanical design for manufacturability and performance. This involves using simulation tools like Finite Element Analysis (FEA) to test how the product will behave under various conditions, such as stress or heat. Engineers also create prototypes—either physical or virtual—to validate engineering product design assumptions and gather feedback from stakeholders. Prototyping helps identify potential issues early on, reducing costly errors later in the production process.

Material Selection and Manufacturing Engineers are responsible for selecting the right materials that balance cost, durability, and performance. This stage often involves sourcing materials that meet regulatory requirements while also being sustainable or cost-effective. Once materials are selected, product design engineers work closely with manufacturers to ensure that the mechanical design allows the product to be produced efficiently at scale while considering ergonomics, aesthetics, and usability for a better user experience.

The Impact of Technology on Engineering Product Development

Modern engineering tools have revolutionized how products are developed:

CAD Software: CAD facilitates engineering product design by allowing product design engineers to create detailed 3D models that can be easily modified, tested, and shared across teams. This software accelerates design iterations, improves accuracy, and reduces time-to-market.

AI Integration: Artificial intelligence (AI) is increasingly being used to optimize designs by exploring multiple configurations rapidly. AI-driven tools can automate repetitive tasks like CAD modeling and provide insights into customer preferences based on data analysis. This leads to more innovative products tailored to specific user needs.

Simulation Tools: FEA and Computational Fluid Dynamics (CFD) software enable engineers to simulate real-world conditions without needing physical prototypes. These tools help optimize designs for strength, durability, efficiency, and performance before any material is wasted in production.

Future Trends in Engineering Product Development

As technology continues to evolve, several trends are shaping the future of engineering in product development:

Agile Development: Cross-functional teams, including product design engineers, are adopting agile methodologies to speed up the development process through iterative sprints. Agile practices allow for faster prototyping and continuous feedback loops.

IoT and Connected Products: The rise of connected devices means that engineers must now design products that integrate seamlessly with other systems through technologies like Wi-Fi or Bluetooth..

Sustainability: With growing environmental concerns, engineers are increasingly focused on designing products that minimize waste, use eco-friendly materials, and reduce energy consumption during manufacturing.

Conclusion

A product design engineer specializing in mechanical design is at the heart of successful engineering product design and development. By leveraging modern tools like CAD, AI-driven optimization, and advanced simulation software, engineers can bring products to market with unparalleled innovation and efficiency than ever before. As technology continues to advance, the role of engineers will only become more critical in shaping the future of product development—ensuring that products not only meet technical specifications but also address consumer needs in a sustainable way while incorporating principles of ergonomics, aesthetics, and usability for optimal user experience.

FARO 3D Scanning Solutions: Bortnick Consulting Services Joins Forces

We are thrilled to announce that Bortnick Consulting Services has officially become a partner of FARO, a global leader in 3D measurement and imaging solutions. This partnership marks a significant milestone for our company as we expand our capabilities to better serve our clients, and soon we will showcase more of our work on our YouTube channel.

How Bortnick Consulting Elevates Scanning Strategies

As an official FARO partner, Bortnick Consulting Services is now equipped to assist in the sale of any FARO product, including the latest laser scanner technology that generates detailed point cloud data. This collaboration allows us to provide our clients with cutting-edge technology solutions, including advanced modeling techniques, tailored to their specific needs. Whether you're looking for precision measurement tools, FARO 3D scanning technology, or advanced imaging systems, we are here to guide you through the selection process and ensure you receive the best solutions available.

The Benefits of Integrating Expert Consulting

In addition to our new role in facilitating FARO product sales, we remain committed to offering competitive rates on 3D scanner rentals, and you can learn more about our services on YouTube. Our goal is to make high-quality technology like FARO 3D scanning, including cutting-edge laser scanner options, point cloud processing, and advanced modeling, accessible and affordable for businesses of all sizes. By combining our expertise with FARO’s innovative products, we are confident in delivering exceptional value and service.

The Future of Precision Engineering and Design

This partnership with FARO 3D scanning reinforces our dedication to providing top-tier consulting services and technological solutions. We look forward to leveraging this collaboration, including the use of a laser scanner for modeling to generate point cloud data and promotion through YouTube, to enhance our offerings and support our clients in achieving their project goals with precision and efficiency.

Mold Imperfections: Troubleshooting for Better Yield

Identifying Common Defects

At Bortnick Consulting Services LLC, we understand the critical importance of precision in injection molding, especially in minimizing the parting line. Even the smallest imperfection, irregularities, or defects, such as cracking, flow lines, or sink marks, can lead to significant issues in the final product. That's why we advocate for the use of advanced technologies like the FARO 3D scanner to enhance mold accuracy and efficiency.

Assessing The Root Causes

FARO 3D scanners are revolutionizing the mold-making industry by providing a faster, more accurate method for detecting imperfections and assessing wall thickness. Traditional methods, such as using fixed coordinate measuring machines (CMMs) or manual tools, can be time-consuming and prone to human error. In contrast, FARO's portable 3D scanning solutions offer several advantages:

Speed and Efficiency: FARO scanners drastically reduce the time required for mold inspection. They can capture millions of data points in a fraction of the time it takes traditional methods, allowing for rapid identification and correction of defects.

Non-contact Measurement: The non-contact nature of laser scanning in injection molding eliminates the risk of damage to delicate mold surfaces while ensuring comprehensive data collection from all angles, including along the parting line and flow lines, and assessing wall thickness to prevent defects, irregularities, and issues like sinking or sink marks.

High Accuracy: With measurement accuracy up to 0.01 millimeters, FARO scanners ensure that every detail is captured precisely, facilitating high-quality mold production.

Enhancing Mold Performance

Using FARO 3D scanners, mold makers can:

Identify Imperfections Early: The scanners provide real-time visualization of scan data, enabling immediate detection of imperfections that might otherwise go unnoticed until later stages of production.

Ensure Design Compliance: By comparing scanned data against CAD models, mold makers can verify that molds meet design specifications, ensure the proper placement of the parting line, and identify potential issues such as flow lines, reducing the risk of costly rework and production delays.

Enhance Quality Control: The comprehensive data collected allows for detailed analysis and reporting, including wall thickness measurements, ensuring that all quality standards are met before molds are used in production, thereby preventing irregularities and defects such as sink marks and cracking.

Solutions for a Better Finish: Conclusion

Incorporating FARO 3D scanning technology into your injection molding process can significantly enhance quality control and operational efficiency. At Bortnick Consulting Services LLC, we are committed to helping you leverage these cutting-edge tools to achieve superior results in your manufacturing processes. By adopting FARO's advanced scanning solutions, you can ensure that your molds are flawless and ready for production, ultimately leading to higher customer satisfaction and reduced costs.

Faro Arm Rental Services for Precision Engineering

In today's fast-paced industrial landscape, precision and adaptability are paramount. At Bortnick Consulting 3D Scanning and Engineering, we understand the diverse needs of businesses seeking top-notch measurement solutions without the hefty investment in permanent equipment. Our FARO Arm rental services provide the perfect solution for companies looking to enhance their capabilities with cutting-edge technology.

Why Choose FARO Arm Rentals?

Cost-Effectiveness: Renting a FARO 3D scanning arm can significantly reduce costs compared to purchasing. By opting for rental, businesses can save up to 50% on expenses, avoiding the substantial capital outlay and depreciation associated with owning such advanced equipment. This financial flexibility allows companies to allocate resources more efficiently, investing in other critical areas of their operations. Flexibility and Convenience: Our rental services offer unparalleled flexibility, enabling businesses to scale their technological needs according to project demands. Whether you require equipment for a day or several months, our customizable rental terms ensure you have access to the latest models and features without long-term commitments. This adaptability is crucial for responding swiftly to changing project requirements. Access to Cutting-Edge Technology: Staying at the forefront of technological advancements is essential for maintaining a competitive edge. Renting from Bortnick Consulting grants you access to the most advanced FARO equipment available, ensuring your projects benefit from the latest innovations in 3D scanning and laser inspection.

Tailored Solutions for Every Need

Every project is unique, and so are our solutions. We offer a wide range of FARO Arms, including models equipped with both contact and non-contact measurement capabilities. This versatility, combined with our portable CMM solutions, allows for precise inspections, CAD comparisons, reverse engineering, and more. Whether you're dealing with complex geometries or require high-speed data capture, our FARO Arms are designed to meet your specific needs.

Local Expertise You Can Trust

Located conveniently near you, Bortnick Consulting is committed to providing exceptional service and support throughout your rental experience. Our team of experts is ready to assist you with setup, training, and any technical inquiries you may have, including those related to portable CMM. We ensure that your rental experience is seamless, allowing you to focus on what truly matters—delivering outstanding results for your projects. In conclusion, renting a FARO Arm from Bortnick Consulting offers a strategic advantage by combining cost savings, flexibility, and access to state-of-the-art technology. Contact us today to learn more about how our rental solutions can empower your business with precision and efficiency.

Enhancing Efficiency Through FARO Arm and Laser Scanning

Efficiency in industrial applications is akin to the precision choreography of a ballet, where every movement is deliberate, synchronized, and optimized to achieve the pinnacle of performance excellence.

Imagine the possibilities.

The FARO arm and 3D laser scanning together illuminate an era of unprecedented accuracy in measurement, unveiling a future where innovation blossoms at the crossroads of technology and creativity.

Understanding FARO Arm Technology

Harnessing the potential of FARO arm technology, industries across the spectrum can achieve unparalleled precision and efficiency, enabling transformative advancements in manufacturing, construction, and beyond.

FARO arms are portable coordinate measuring machines (PCMMs).

These articulated arms have redefined the way we capture data, offering robust (yet user-friendly) solutions for complex measurement challenges across various sectors, especially when integrated with CAD drawings for enhanced precision.

With these tools, industries gain a profound advantage in understanding and perfecting their processes, reducing errors, and enhancing productivity.

These instruments open opportunities for precision in quality control and reverse engineering, feeding vital data into sophisticated models and simulations that drive informed decision-making.

Ultimately, the power of the FARO arm lies in its ability to transform potential into performance, setting new standards of excellence in a connected world.

How FARO Arm Enhances Industrial Efficiency

Through its potential to revolutionize measurement methodologies, FARO Arm stands as a pivotal element in enhancing industrial efficiency worldwide, transforming precision into productivity and inspiring unprecedented levels of accuracy.

Across industries, these tools serve as the backbone, enabling unparalleled data accuracy.

Notably, advanced technologies like laser scanning and laser beams facilitated by FARO Arms enable industries to capture and model intricate surfaces.

This dynamic toolset allows for seamless integration into existing workflows, enhancing operational capacity and reducing turnaround time.

Many businesses are experiencing unparalleled growth by leveraging FARO Arms, translating this into concrete business value by minimizing errors and maximizing resource utilization, thus creating a ripple effect of efficiency.

Moreover, integrating FARO Arm technology transforms how industries perceive and tackle challenges. Tomorrow’s industrial successes begin today, anchored in technology's progressive embrace to redefine what's achievable.

Key Benefits of Laser Scanning

Laser scanning revolutionizes perception, driving a realm of data-rich innovation, where details thrive. By transforming complex shapes into precise digital replicas using laser beams, laser scanning empowers industries with a treasure trove of actionable insights, tearing down barriers and building bridges to greater efficiency.

The precision and adaptability of a tool like the FARO Arm, equipped with "laser scanning," herald a new era of industrial advancement. It brings to the fore a sphere of enhanced documentation, ensuring accuracy and facilitating harmonious collaboration. Through laser scanning, the blueprint of the future is rendered visible, paving pathways where imagination meets execution for industrious applications.

Precision Measurement

Polyworks, paired with FARO Arm laser scanning, offers an unparalleled level of precise measurement, enabling industries to redefine accuracy standards. This duo marks an era of unprecedented precision in modern manufacturing.

By effortlessly digitizing complex geometries, Polyworks ensures industries can create precise digital models. Laser scanning, along with CAD drawings, provides an invaluable detail, revolutionizing the way that products are designed and inspected.

Industries report accuracy improvements of up to 45%, thanks to the precision of laser scanning technology.

With the precision and reliability delivered by FARO Arm laser scanning, manufacturers can confidently align their production processes. This ensures each component meets stringent specifications, ultimately leading to superior product quality and customer satisfaction. Laser scanning not only measures today’s needs but also strategically positions businesses for future advancements.

Reduced Inspection Time

Laser scanning technology has revolutionized the industrial inspection process, drastically cutting down the time required for thorough evaluations.

Accelerated Data Capture: Quick and efficient collection of comprehensive data.

Streamlined Processes: Significantly reduces the redundancy inherent in traditional inspection methods.

Real-Time Analysis: Provides instant insights, enabling immediate corrective actions.

Adaptable Solutions: Suitable for a variety of industries and applications.

By integrating a FARO Arm and laser scanning, businesses achieve optimal efficiency, minimizing production downtime and enhancing workflow.

This empowering technology inspires industries to embrace innovation, ensuring fast, reliable, and precise inspections that meet dynamic demands.

Industrial Applications of FARO Arm

In today’s fast-paced industrial landscape, the FARO Arm stands as a beacon of transformative capability, redefining precision and efficiency. This remarkable tool supports diverse sectors, from automotive manufacturing to aerospace engineering, by providing exact measurement solutions and enhancing complex assembly processes. Its dynamic adaptability offers unparalleled accuracy, facilitating intricate design verifications and rigorous quality control, ultimately driving operational excellence and fostering a culture of continuous innovation.

Automotive Industry

The automotive sector thrives on precision and innovation, making FARO Arm and laser scanning indispensable tools for success.

Quality Control: Ensures exact measurements and identifies discrepancies in vehicle components efficiently.

Design Optimization: Aids in the refinement of vehicle prototypes through accurate 3D modeling.

Reverse Engineering: Facilitates the creation of digital replicas of existing car parts, enhancing design modifications.

Production Efficiency: Speeds up assembly line processes by providing real-time data and reducing fitment issues.

By integrating laser scanning technology, automotive experts can streamline production and bolster product quality significantly.

These innovations not only catalyze groundbreaking automotive designs but also elevate industry standards and inspire confidence in future possibilities.

Aerospace Applications

The aerospace industry is synonymous with precision, complexity, and cutting-edge technology. This sector demands unparalleled accuracy and reliability in every component and structure.

In this sphere, FARO arm and laser scanning technology play a pivotal role by conducting comprehensive inspections and capturing intricate geometries. This ensures superior accuracy in component fabrication and assembly, especially when working with cad drawings. The use of Polyworks software further enhances these capabilities, making data management and analysis seamless.

3D laser scanning utilizing laser beams allows aerospace engineers to create precise digital models that assist in the assessment and optimization of aerodynamics. These high-fidelity models are crucial for simulating flight conditions and enhancing the performance of aircraft parts. Such advancements empower engineers to test and iterate designs swiftly.

Moreover, this technology is indispensable for quality assurance, detecting minute flaws that might compromise safety or performance. By integrating these tools, the aerospace sector not only adheres to strict safety standards but also accelerates innovation in aircraft design and maintenance.

Harnessing laser scanning and FARO arms propels the aerospace industry toward a more efficient, innovative, and secure future.

Integrating Polyworks with FARO Arm

With the advent of advanced technologies, integrating Polyworks with FARO Arm has become transformative in precision engineering and quality control.

The synergy of the FARO Arm with Polyworks offers a comprehensive solution for capturing accurate geometries, allowing for meticulous inspections and data analysis. This integration facilitates enhanced interoperability, enabling engineers to effortlessly bridge the gap between physical measurements and virtual models, thereby revolutionizing manufacturing processes.

Specifically, this integration acts as a catalyst for streamlining workflow efficiencies. By leveraging these advanced systems, professionals can achieve reduced project lead times while maintaining rigorous standards of quality assurance and accuracy.

Ultimately, the seamless integration of FARO Arm with Polyworks empowers industries to propel forward with confidence, knowing their measurement tools are both reliable and precise. This enables companies not only to meet but exceed global benchmarks in manufacturing, enhancing their competitive edge and paving the way for breakthroughs in various industrial applications.

Faro 3D Scanning Rental: Best Prices Guaranteed

Precision is the cornerstone of innovation, much like the intricate gears of a finely-tuned watch drive its seamless movement.

With Faro 3D scanning rental services, you are assured access to top-tier technology and unparalleled accuracy, propelling your projects to new heights.

Why Rent a Faro 3D Scanner?

Consider the myriad advantages: unparalleled measurement precision, ease of use, and adaptability across diverse applications. Renting provides immediate access to cutting-edge technology without the heavy initial investment. This empowers your team to swiftly achieve accurate, reliable results for complex projects, facilitating innovation and efficiency.

Cost-Effectiveness

Renting FARO 3D scanning equipment allows you to reduce expenditures while gaining access to top-tier technology.

Renting a FARO 3D scanner can save up to 50% compared to purchasing new equipment outright.

With faro 3d scanning rental, businesses can sidestep the high capital costs associated with owning state-of-the-art technology. This facilitates more frequent upgrades, ensuring the latest advancements are always within reach.

Moreover, the flexibility of rental terms—from daily to monthly rates—enables precise budget management tailored to project-specific needs, empowering organizations to allocate resources more efficiently and effectively.

Flexibility and Convenience

Experience unprecedented adaptability with FARO 3D scanning rental.

One of the most significant advantages of renting FARO 3D scanning equipment is the unparalleled flexibility it offers. This enables businesses to scale their technological requirements up or down based on specific project demands, without committing to long-term investments. Consequently, rental agreements can be customized not only in terms of duration but also with respect to the models and features required, providing significant operational agility.

Adapt to project needs effortlessly.

This flexibility translates to substantial operational efficiencies - whether an urgent need arises to expand capacity or to access specialized functions for a limited period - rental options deliver cost-effective and hassle-free solutions.

Our rental services are designed around innovation and customer satisfaction, empowering businesses to stay at the forefront of technological advancements. Clients can swiftly implement cutting-edge scanning solutions without the constraints of ownership, maximizing efficiency and driving project success.

Cost Comparison: Renting vs Buying

When evaluating FARO 3D scanning rental, an astute comparison to purchasing reveals immediate financial benefits. Renting circumvents substantial upfront costs associated with buying equipment.

Additionally, by opting for a rental service, companies can avoid depreciation expenses.

This approach is particularly advantageous for businesses needing scanning solutions for short-term projects, enabling flexibility without the burden of ownership. Renting also allows access to the latest models and advanced features.

In comparing the two options, it becomes clear renting offers a practical and financially savvy solution for many enterprise needs. By choosing rental, companies can allocate resources more efficiently, remain agile in fluctuating market conditions, and stay at the pinnacle of technological innovation without the commitment of a permanent investment.

Best Practices for Renting Faro 3D Scanners

Ensure you know your project requirements first.

A thorough understanding of your project's scope and specifications will streamline the rental process. By identifying whether your tasks necessitate high-resolution scans, large-scale areas, or specialized features, you can select the most suitable Faro 3D scanner model. Consequently, alignment of equipment capabilities to project needs can enhance data accuracy and productivity.

Confirm the rental period accurately.

Determine the precise duration for which you need the scanner. Estimating this period meticulously ensures you avoid unnecessary costs and maintain seamless project timelines.

Verify service and maintenance clauses.

Before finalizing the rental agreement, inquire about the service and support options provided by the rental agency. This could include on-site support, training, and maintenance services, which are critical for mitigating downtime and maintaining optimal performance. SaaS models often offer the added advantage of tech support and regular updates.

Review user feedback and support quality meticulously.

Check for reviews and ratings of the rental service from other users. This can provide invaluable insights into the reliability and technical support of the provider. Additionally, considering the market leaders known for excellent customer service can significantly bolster your project's prospects, ensuring that challenges are swiftly addressed, maintaining project momentum, and securing the desired outcomes.

Customer Reviews and Testimonials

Here's what our customers are saying.

A multitude of our clients have shared their satisfaction with our Faro 3D scanning rental services. They repeatedly commend the precision, reliability, and efficiency of our equipment, alongside the outstanding support provided by our dedicated team. For professionals demanding impeccable results, their feedback confirms that our solutions deliver, time and again.

Rated highly among industry leaders.

Customers consistently appreciate our commitment to excellence and prompt support. They highlight how these facets enhance their workflows, minimizing disruptions and maximizing productivity.

From architects to engineers, our renters span a wide range of professions and projects. Their glowing testimonials substantiate our claim of providing top-tier Faro 3D scanning rentals at unmatched prices. Each review motivates us to continue elevating our service quality, ensuring every client reaps the full advantages of advanced 3D scanning technology.

Maximizing Value from Your Faro 3D Scanner Rental

Optimize usage with meticulous planning before execution.

Advanced strategizing before deployment ensures maximum benefits. Clearly outline project objectives and identify specific areas where the Faro 3D scanner can excel in delivering high-resolution data. Thorough preparation is key to obtaining precise measurements that form the foundation for superior project outcomes, substantially enhancing the return on investment.

Always use cutting-edge scanning software.

Maximize efficiency by leveraging the latest software - this can significantly elevate data accuracy and the overall user experience. Engaging with intuitive, user-friendly interfaces can streamline the scanning process.

Request expert training for your team.

With proper training, your team can harness the full potential of the Faro 3D scanner, reducing errors and increasing productivity. Advanced training ensures that your team is proficient in both hardware and software, leading to smoother project execution.

By integrating these strategies, you ensure that every minute of rental time is productive and cost-effective. Let 2023 be the year you unlock new dimensions of innovation, driving your projects to unprecedented heights with the power of Faro 3D scanning technology. Remember, investing in knowledge and preparation today paves the way for future success.

Why Rent From Bortnick Consulting?

At Bortnick Consulting, we're committed to providing cutting-edge solutions for your metrology needs. We're thrilled to highlight our flexible shipping and renting options for the state-of-the-art FARO Quantum Arm with Laser Attachment. This advanced tool offers unparalleled precision and versatility, ensuring your projects are executed with the highest accuracy.🔹 Why Choose Our FARO Quantum Arm?

Unmatched Precision: Achieve exceptional accuracy with our FARO Quantum E MAX 2.0m 7-axis arm, equipped with the FAROBlu xP laser line scanner.

Versatile Applications: Whether you need intricate probing or high-resolution scanning, our FARO arm delivers outstanding results.

Flexible Rental Terms: Tailor your rental duration to fit your project timeline—whether it's a day, a week, or longer, we've got you covered.

Our team is dedicated to supporting your success, offering expert guidance and ensuring you have the right equipment exactly when you need it. Experience the pinnacle of metrology technology with Bortnick Consulting's flexible solutions.Contact us today to explore how our FARO Quantum Arm can enhance your project outcomes! 📞

States we ship to:

FARO Arm Rental Alabama, AL

FARO Arm Rental Alaska, AK

FARO Arm Rental Arizona, AZ

FARO Arm Rental Arkansas, AR

FARO Arm Rental California, CA

FARO Arm Rental Colorado, CO

FARO Arm Rental Connecticut, CT

FARO Arm Rental Delaware, DE

FARO Arm Rental Florida, FL

FARO Arm Rental Georgia, GA

FARO Arm Rental Hawaii, HI

FARO Arm Rental Idaho, ID

FARO Arm Rental Illinois, IL

FARO Arm Rental Indiana, IN

FARO Arm Rental Iowa, IA

FARO Arm Rental Kansas, KS

FARO Arm Rental Kentucky, KY

FARO Arm Rental Louisiana, LA

FARO Arm Rental Maine, ME

FARO Arm Rental Maryland, MD

FARO Arm Rental Massachusetts, MA

FARO Arm Rental Michigan, MI

FARO Arm Rental Minnesota, MN

FARO Arm Rental Mississippi, MS

FARO Arm Rental Missouri, MO

FARO Arm Rental Montana, MT

FARO Arm Rental Nebraska, NE

FARO Arm Rental Nevada, NV

FARO Arm Rental New Hampshire, NH

FARO Arm Rental New Jersey, NJ

FARO Arm Rental New Mexico, NM

FARO Arm Rental New York, NY

FARO Arm Rental North Carolina, NC

FARO Arm Rental North Dakota, ND

FARO Arm Rental Ohio, OH

FARO Arm Rental Oklahoma, OK

FARO Arm Rental Oregon, OR

FARO Arm Rental Pennsylvania, PA

FARO Arm Rental Rhode Island, RI

FARO Arm Rental South Carolina, SC

FARO Arm Rental South Dakota, SD

FARO Arm Rental Tennessee, TN

FARO Arm Rental Texas, TX

FARO Arm Rental Utah, UT

FARO Arm Rental Vermont, VT

FARO Arm Rental Virginia, VA

FARO Arm Rental Washington, WA

FARO Arm Rental West Virginia, WV

FARO Arm Rental Wisconsin, WI

FARO Arm Rental Wyoming, WY

The Benefits of Renting a FARO 3D Scanning Arm

Renting a FARO Arm from Bortnick Consulting offers numerous benefits for businesses seeking precision in inspection and 3D scanning without the commitment of purchase. Our arm rental services provide access to cutting-edge scanning technology and laser inspection tools, allowing you to leverage FARO equipment for detailed trend analysis and industry intelligence. With flexible rental options, you can efficiently manage your inspection technology needs, ensuring high-quality 3D surveying and laser scanning for your projects.

Overcoming Traditional Reverse Engineering Challenges

Reverse engineering has long been a crucial process in the automotive industry, especially when dealing with legacy vehicles like the 1972 GMC Jimmy. Traditionally, reverse engineering involved painstaking manual measurements and drawings, which were not only time-consuming but also prone to errors. When I set out to reverse engineer a car seat bracket from this classic model, the challenges of traditional methods became immediately apparent.

Challenges of Traditional Reverse Engineering

Manual Measurements: Gathering accurate measurements manually can be labor-intensive and imprecise, especially with complex parts like a car seat bracket.

Error-Prone: Human error is a significant risk, leading to inaccuracies that can affect the functionality and safety of the reproduced part.

Time-Consuming: The process of measuring, drawing, and verifying can take days or even weeks, delaying project timelines.

Lack of Precision: Traditional methods struggle to capture intricate details and complex geometries, which are essential for creating an accurate replica.

Revolutionizing the Process with FARO Arm and PolyWorks

At Bortnick Consulting, we have embraced cutting-edge technology to overcome these challenges. The integration of the FARO Arm, a portable coordinate measuring machine (CMM), with PolyWorks software has transformed our reverse engineering process.

Advantages of 3D Scanning

Precision and Accuracy: The FARO Arm allows for precise 3D scanning of the car seat bracket, capturing every detail with high accuracy. This ensures that the reverse-engineered part matches the original specifications.

Efficiency: What once took days can now be completed in hours. The FARO Arm quickly captures data, which is then processed by PolyWorks to create detailed 3D models.

Error Reduction: The automated nature of 3D scanning minimizes human error, leading to more reliable outcomes.

Comprehensive Data: The detailed point clouds generated by the FARO Arm provide a complete digital representation of the part, which can be used for further analysis and modification.

PolyWorks Software

PolyWorks plays a crucial role in this process by converting the scanned data into usable CAD models. It allows us to:

Create Accurate Models: Transform point clouds into polygonal models and ultimately into CAD-friendly formats.

Modify and Optimize: Make necessary adjustments to the design, ensuring the part meets current standards and requirements.

Streamline Workflow: The intuitive interface and powerful features of PolyWorks make it easier to manage and manipulate complex data.

Conclusion

The combination of the FARO Arm and PolyWorks software has revolutionized how we approach reverse engineering at Bortnick Consulting. By leveraging these advanced technologies, we can efficiently and accurately recreate parts like the 1972 GMC Jimmy car seat bracket, ensuring they meet modern standards while preserving the integrity of classic designs. This approach not only enhances our capabilities but also empowers us to deliver superior solutions to our clients.

Exploring the PolyWorks Folder System: A Comprehensive Guide for 3D Scanning and Reverse Engineering

Understanding the PolyWorks Folder System

In this introductory episode, we delve into the PolyWorks folder system, which is essential for anyone involved in 3D scanning and 3D reverse engineering. Proper folder organization is crucial for managing your projects efficiently, ensuring that all your data is easily accessible and well-structured.

🔍Watch the video here: PolyWorks Folder System

Key Highlights

3D Scanning: Learn how to organize your 3D scan data effectively within PolyWorks.

How to Use PolyWorks: Step-by-step guidance on setting up and managing your PolyWorks workspace.

How to Use FARO Arm: Integration tips for using the FARO arm with PolyWorks, enhancing your metrology capabilities.

3D Reverse Engineering: Techniques for structuring your reverse engineering projects for optimal workflow.

Why This Tutorial is Important

This tutorial is perfect for both beginners and experienced users looking to enhance their skills. By understanding the PolyWorks folder system, you can streamline your workflow, making it easier to manage complex projects and improve your overall efficiency.

Join the Conversation

💬What do you want to see next?We value your input! Let us know in the comments what topics or tools you'd like us to cover in future videos. Your feedback helps us create content that is most relevant and useful to you.

#3DScanning #HowToUsePolyWorks #HowToUseFAROArm #3DReverseEngineering #Metrology #PolyWorksTutorial #FAROArm #3DInspection

Investing in New Machinery and Software: Challenges and Solutions

In today's fast-paced industrial landscape, staying competitive often means investing in new machinery and software. At Bortnick Consulting, we understand the challenges that come with these investments, from high initial costs to steep learning curves and integration issues.

One major challenge is the significant financial outlay required for new equipment and software. Companies must evaluate the return on investment (ROI) to ensure benefits outweigh costs. Additionally, the implementation phase can be disruptive, requiring careful planning to minimize downtime and maintain productivity.

Training and adaptation are also critical hurdles. New machinery and software often come with a learning curve that can slow down operations. This is where specialized training becomes invaluable. At Bortnick Consulting, we specialize in FARO 3D Scanning Arm rentals and PolyWorks training, helping companies seamlessly integrate these advanced tools into their workflows.

To support our clients and the broader community, we are excited to announce a new blog series dedicated to tips and tricks for using PolyWorks. Starting this Friday, and continuing every Friday, we will share insights and practical advice on "How to Use PolyWorks," "Introduction to PolyWorks," "Reverse Engineering," and "Quality Inspection." Whether you're a seasoned user or just getting started, our series will provide valuable information to enhance your skills and improve your efficiency.

Stay tuned for our first post this Friday, and join us on this journey to mastering PolyWorks. Together, we can overcome the challenges of investing in new technology and drive our industries forward.

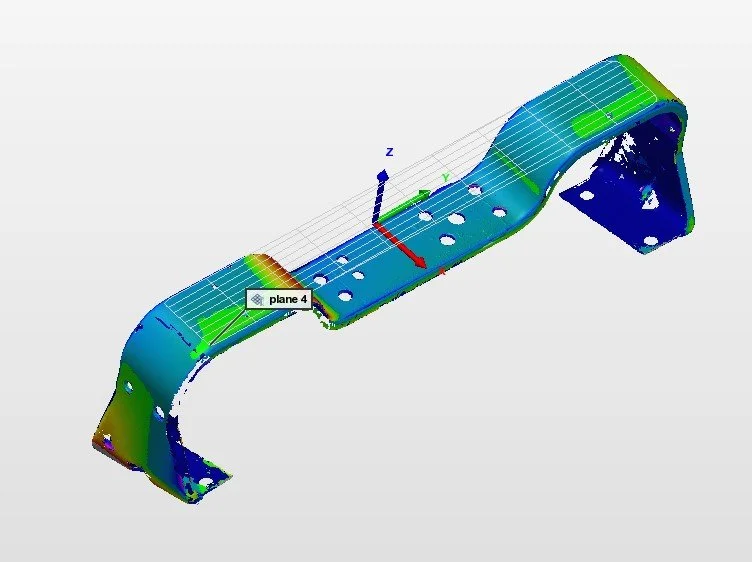

Leveraging Finite Element Analysis (FEA) from 3D Scanned Parts to Enhance Your Manufacturing Business

In the ever-evolving landscape of manufacturing, staying ahead of the curve requires adopting cutting-edge technologies that streamline processes, reduce costs, and improve product quality. One such technology is Finite Element Analysis (FEA), particularly when combined with 3D scanning. This powerful combination can revolutionize how you design, test, and optimize your products. In this blog post, we will explore what FEA is, how it works with 3D scanned parts, and the myriad benefits it offers to your manufacturing business.

What is Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a computerized method used to predict how products will react to real-world forces, such as heat, vibration, stress, and other physical effects. By breaking down a complex object into smaller, manageable finite elements, FEA allows engineers to simulate and analyze the behavior of each element under various conditions. This method provides detailed insights into the performance and potential failure points of a design before any physical prototypes are built.

How FEA Works with 3D Scanned Parts

Combining FEA with 3D scanning technology brings a new level of precision and efficiency to the design and testing process. Here’s how it works:

1. 3D Scanning: The process begins with 3D scanning the physical part or prototype. This creates a highly accurate digital model of the object, capturing every detail and dimension.

2. Mesh Generation: The 3D scanned model is then converted into a mesh, consisting of numerous finite elements. The quality of the mesh is crucial for the accuracy of the FEA results.

3. Material Properties and Boundary Conditions: Engineers assign material properties and define boundary conditions, such as forces, pressures, and constraints, to the mesh.

4. Simulation: The FEA software simulates how the object will behave under the specified conditions. This involves solving complex mathematical equations for each finite element.

5. Post-Processing: The results are analyzed and visualized, showing stress distribution, deformation, temperature gradients, and other critical factors. Engineers can then make informed decisions to optimize the design.

Benefits of Using FEA with 3D Scanned Parts

1. Enhanced Accuracy and Detail

3D scanning captures the exact geometry of a part, ensuring that the FEA model is highly accurate. This level of detail is particularly beneficial for complex geometries and intricate designs that are difficult to model manually.

2. Reduced Prototyping Costs

By simulating the performance of a design virtually, FEA reduces the need for multiple physical prototypes. This not only saves time but also significantly cuts down on material and labor costs associated with prototyping.

3. Improved Design Optimization

FEA allows engineers to test various design iterations quickly and efficiently. By analyzing different configurations and materials, they can optimize the design for performance, weight, and cost, leading to better and more innovative products.

4. Increased Safety and Reliability

FEA can simulate extreme conditions and potential failure modes, providing insights into how a product will perform under stress. This helps in designing safer and more reliable products, which is crucial in industries such as aerospace, automotive, and construction.

5. Faster Time-to-Market

The combination of 3D scanning and FEA accelerates the design and testing phases, allowing for quicker iterations and faster decision-making. This leads to a shorter overall product development cycle and a faster time-to-market.

Conclusion

Incorporating Finite Element Analysis with 3D scanned parts into your manufacturing process can provide a competitive edge by enhancing accuracy, reducing costs, and improving product quality. By leveraging these advanced technologies, you can optimize your designs, ensure safety and reliability, and bring innovative products to market faster. If you are looking to stay ahead in the manufacturing industry, it’s time to explore the potential of FEA and 3D scanning for your business.

For more information on how FEA can benefit your specific applications, or to discuss your project needs, feel free to contact us. Let’s work together to transform your ideas into reality with precision and efficiency.

The Crucial Role of Consulting Engineers Across Industries

Understanding the Multifaceted Arena

In the rapidly evolving world of technology and business, the role of consulting engineers has never been more critical. As specialists who bridge the gap between innovation and practical application, consulting engineers must possess a deep understanding of various industries to provide tailored solutions that meet specific client needs.

The Art of Adaptation

The essence of a consulting engineer's role lies in their ability to adapt. Each industry, whether it be healthcare, manufacturing, or retail, comes with its unique set of challenges and requirements. The ability to swiftly shift perspectives and apply engineering principles across these diverse landscapes is what makes a consulting engineer invaluable.

Continuous Learning and Innovation

Continuous learning is the cornerstone of effective consulting. Staying abreast of the latest technologies, methodologies, and industry trends is not just beneficial; it's essential. This ongoing education allows consulting engineers to offer the most current and effective solutions, ensuring that their clients are always at the cutting edge of efficiency and innovation.

Building Relationships and Trust

Beyond technical expertise, successful consulting engineers build strong relationships based on trust and understanding. They listen to their clients' needs and concerns, ensuring that the solutions provided are not only effective but also aligned with the client's long-term goals and company culture.

Conclusion

The role of a consulting engineer is dynamic and demands a high level of expertise, adaptability, and interpersonal skills. By understanding the intricacies of various industries and continuously enhancing their knowledge, consulting engineers play a pivotal role in helping businesses navigate the complexities of modern-day challenges.In conclusion, whether you are a stakeholder in technology, engineering, or business, recognizing and leveraging the expertise of consulting engineers can be your pathway to innovation and success in an ever-changing world.

#ConsultingEngineering #IndustryKnowledge #Adaptability #ContinuousLearning #Innovation

Revolutionizing 3D Scanning and 3D Design: The Power of the 3Dconnexion Mouse

Unveiling the 3Dconnexion Mouse

The 3Dconnexion Mouse is not your ordinary mouse. Designed with the specific needs of 3D professionals in mind, it transcends the limitations of traditional mice, offering a more intuitive and natural way to interact with digital 3D environments. Whether it's for 3D scanning, design, or CAD work, this mouse provides a level of control that is both sophisticated and unparalleled.

Key Features:

Benefits for CAD Design and Reverse Engineering:

Enhanced Productivity

The intuitive control offered by the 3Dconnexion Mouse streamlines the design process, allowing for quicker manipulation of 3D scenes. This efficiency is invaluable in reverse engineering, where precision and speed are paramount.

Improved Accuracy

With the 6DoF sensor, every movement is precise, from the broadest pan to the smallest zoom. This accuracy is crucial when working on complex CAD designs, ensuring that every detail is just right.

Seamless Integration

The 3Dconnexion Mouse is compatible with most CAD software, making it a versatile tool in your design arsenal. This seamless integration means less time learning new tools and more time perfecting your designs.

Optimization for 3D Scanning, Design, and CAD

To ensure that this post reaches those who can truly benefit from the 3Dconnexion Mouse, it's optimized for search engines with keywords such as "3D scanning," "3D design," and "3D CAD."

By sharing my personal experience and the tangible benefits of incorporating this mouse into my workflow, I aim to connect with fellow professionals and enthusiasts in the field, fostering a community of innovation and precision in 3D design.

In conclusion, the 3Dconnexion Mouse has revolutionized the way I approach CAD design and reverse engineering. Its blend of functionality, ergonomics, and precision has not only enhanced my productivity but also made the design process more enjoyable. For anyone involved in 3D scanning, design, or CAD work, I cannot recommend this tool highly enough. It's not just a mouse; it's your next step towards more efficient, accurate, and enjoyable 3D design work. For more insights into the tools and technologies shaping the future of 3D design, stay tuned to BortnickConsulting.com. Together, let's push the boundaries of what's possible in the world of 3D CAD.

How the FARO Arm 3D Scanner and PolyWorks Revolutionized a Client's Production Line

In the dynamic world of manufacturing, precision and efficiency are paramount. At Bortnick Consulting, we recently demonstrated the power of combining FARO Arm technology with PolyWorks software to address and resolve production discrepancies for a valued client. This blog post explores the intricate process and the impactful results of our reverse engineering solution.

The Production Challenge:

Our client was confronted with a significant challenge - the parts produced on their manufacturing line were not matching the original CAD drawings, leading to costly production errors and delays.

The FARO Arm and PolyWorks Solution:

To tackle this issue head-on, we employed the FARO Arm, a sophisticated portable coordinate measuring machine (CMM), in conjunction with PolyWorks, the leading reverse-engineering and inspection software. This powerful combination allowed us to scan the sheet metal parts with unparalleled precision, creating detailed point clouds that PolyWorks software could then analyze and modify for tooling requirements.

The Analysis and Correction Process:

Through detailed analysis, we identified the discrepancies between the manufactured parts and the original drawings. Using PolyWorks, we were able to reverse engineer the parts, refine the drawings, and ensure a perfect match between the design and the physical components.The Outcome:Our client witnessed a transformation in their production process. With the corrected drawings, they achieved higher efficiency, reduced waste, and maintained their commitment to quality, all without incurring additional costs.

Our experience with the FARO Arm and PolyWorks highlights our commitment to leveraging advanced technology to provide customized solutions. At Bortnick Consulting, we empower small companies with the tools and strategies needed for success, ensuring they can compete on the same level as larger corporations.If you're facing similar production challenges, we invite you to reach out.

Streamline Your Production with Expert 3D Scanner Rental Services

In today’s fast-paced production environment, having the right tools at your disposal is not just an advantage—it's a necessity. At Bortnick Consulting, we understand the critical role that precision measurement plays in maintaining the quality and efficiency of your production process. That's why we offer top-of-the-line 3D scanner rental services, including FARO Arm rental and laser scanner rental, to keep your operations running smoothly.

Why Rent a 3D Scanner?

Renting a 3D scanner can be a game-changer for your business. Here are just a few reasons why our clients choose to rent instead of purchase:

Flexibility: Our rental terms are designed to fit your project's timeline, whether you need a scanner for a day, a week, or a month.

Cost-Effectiveness: Avoid the hefty upfront investment of purchasing equipment. With our rental services, you only pay for the time you need.

Latest Technology: Gain access to the most advanced 3D laser scanner rental options without the responsibility of maintenance or upgrades.

Custom Solutions: Every project is unique, and so are our rental solutions. We tailor our services to meet your specific requirements.

FARO Arm Rental: Precision at Your Fingertips

The FARO Arm is an industry-leading portable coordinate measuring machine (CMM) that offers unparalleled accuracy for complex measurement and inspection tasks. By choosing our FARO Arm rental service, you can:

Ensure product quality with precise 3D measurements.

Easily integrate into your existing workflow with minimal disruption.

Benefit from our expert support and guidance throughout your rental period.

Laser Scanner Rental: Capture Every Detail

Our laser scanner rental options provide you with the ability to capture detailed 3D data of physical objects and environments. With this technology, you can:

Create accurate digital twins for reverse engineering or quality control.

Reduce manual measurement errors and increase efficiency.

Access high-resolution data for comprehensive analysis and reporting.

How Bortnick Consulting Supports Your Goals

At Bortnick Consulting, we're more than just a rental service—we're your partner in production excellence. Here's how we support your goals:

Expertise: Our team has extensive knowledge of 3D measurement technology and its applications across various industries.

Support: We provide thorough training and support to ensure you get the most out of your rental experience.

Customization: We listen to your needs and customize our rental solutions to align with your project objectives.

Get Started with 3D Scanner Rental Today

Ready to enhance your production process with high-quality 3D scanning capabilities? Contact Bortnick Consulting to discuss your needs and discover how our 3D scanner rental services can benefit your business. Let us help you maintain your production momentum with the right tools at the right time.

A Leap into the Future with Laser Precision

The article, "Data and Precision from Laser-Based 3D Metrology is Critical Next Step in the Modernization of Manufacturing," underscores the significance of 3D laser-driven metrology in informing and optimizing the build, design, and quality processes. As we embrace Industry 4.0, the convergence of artificial intelligence, machine learning, and the Internet of Things (IoT) with advanced metrology solutions is setting a new benchmark for quality and efficiency.

Automotive and Aerospace: Trailblazers of Innovation

Leading the charge are the automotive and aerospace sectors, where precision is paramount. These industries have long understood that the path to modernization is paved with data and precision. By integrating 3D metrology into their quality assurance and quality control departments, they are not only enhancing product quality but also streamlining their manufacturing processes.

Bortnick Consulting Services: Your Partner in Precision

At Bortnick Consulting Services, we specialize in 3D scanning and reverse engineering services that align with this vision of modernization. Our expertise in 3D metrology positions us as a key player in supporting industries looking to rent or implement these technologies. Whether it's for a short-term project or a long-term transformation, our 3D scanning solutions offer the accuracy and detail that are critical in today's competitive landscape.

Embracing the Digital Transformation

As we look to the future, it's clear that the adoption of advanced metrology will continue to expand beyond automotive and aerospace. Industries such as medical devices, electronics, power generation, and construction are recognizing the need for stringent quality measures. Metrology is no longer a downstream process—it's moving upstream, becoming an integral part of the manufacturing lifecycle.

Join the Revolution

We invite you to join us in this revolution. Whether you're looking to rent state-of-the-art 3D scanning equipment or seeking expertise in reverse engineering, Bortnick Consulting Services is your gateway to precision and innovation. Let's harness the power of 3D metrology together and take the next step in the modernization of manufacturing.

Personalizing Your Space: The Art of 3D Scanning and Reverse Engineering

The Challenge: A Sliding Floor Vent Cover

Imagine a sleek, flat floor vent cover with no mounting fixtures, free to roam across your floor with every gust of wind. It's not just an inconvenience; it's a tripping hazard and a detraction from the aesthetic of your room.

The Solution: Reverse Engineering with Precision

Enter the world of 3D scanning and reverse engineering. With my trusty 3D scanner, I can capture the exact dimensions and contours of your vent cover and the surrounding floor area. This data becomes the blueprint for designing an adapter that's a perfect match for your vent.

The Design: A Custom Adapter with a Secure Mount

The custom adapter I create isn't just a stopgap; it's a thoughtfully designed piece that complements your vent cover. By utilizing the existing holes in the plate, the adapter anchors securely into the subfloor without any unsightly alterations. It's a simple yet elegant solution that maintains the integrity of your floor design.

The Result: Harmony Restored

With the adapter in place, your vent cover stays put, exactly where it's meant to be. No more sliding, no more adjusting – just a seamless part of your home that works as it should. And the beauty of this solution? It's crafted specifically for you, for your home, and for your peace of mind.

Embracing Innovation for Everyday Problems

This is just one example of how 3D scanning and reverse engineering can turn a common annoyance into a non-issue. It's about using innovative technology to create personalized solutions that enhance our living spaces and our lives.

How 3D Scanning is Saving the Car Restoration Market

The car restoration market is at a pivotal juncture, with 3D scanning technology leading the charge towards innovation and precision. This groundbreaking approach is not just enhancing the way we restore classic cars; it's redefining it.

The Challenge of Classic Car Restoration:

Restoring classic cars is an art, requiring a meticulous eye for detail and a deep respect for the vehicle's original craftsmanship. One of the biggest challenges has always been the scarcity of original parts and the need for absolute precision in the restoration process.

The Role of 3D Scanning in Car Restoration:

3D scanning technology has emerged as a powerful tool in the car restorer's arsenal. By capturing detailed 3D images of car parts, restorers can now replicate parts with an accuracy that was previously unattainable. This not only preserves the authenticity of the restoration but also significantly speeds up the process.

Benefits of 3D Scanning for Car Restoration:

Accuracy and Precision: 3D scanning captures the exact dimensions and curves of car parts, ensuring that replacements are a perfect match.

Time and Cost Efficiency: The technology reduces the time spent on manual measurements and the overall cost of the restoration project.

Reverse Engineering: For parts that are no longer available, 3D scanning allows restorers to reverse engineer and produce them, keeping the restoration true to its original form.

Future of Car Restoration with 3D Scanning:

The integration of 3D scanning in car restoration is just the beginning. As the technology evolves, we can expect even greater accuracy, faster processing times, and more innovative solutions to restoration challenges.

3D scanning is not just saving the car restoration market; it's propelling it into a new era of precision and efficiency. By embracing this technology, restorers can ensure that classic cars are not only preserved but are brought back to their former glory with unparalleled accuracy. For those passionate about car restoration, the message is clear: the future is in 3D scanning. Embrace this technology to take your restoration projects to the next level and keep the legacy of classic cars alive for future generations. These posts are designed to highlight the transformative impact of 3D scanning technology in the car restoration industry, emphasizing its benefits in terms of accuracy, efficiency, and innovation.